Introduction/Overview

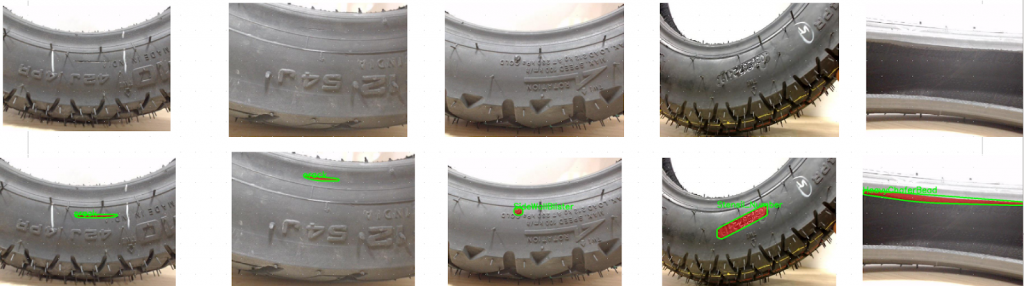

A leading tyre manufacturer aimed to streamline its inspection process for Tyre Identification Numbers (TIN). Manual methods were slow, prone to errors, and unable to scale for a daily throughput of 10,000+ tyres. By implementing an automated visual inspection system, the client sought to reduce operational costs and enhance product quality.