Client Overview

The facility, a key player in aviation fuel logistics, manages high volumes of vehicles and personnel within a sensitive and high-risk operational environment.

With critical areas including pump houses, calibration stations, unloading and loading bays, and expansive perimeters, the need for robust surveillance and efficient process automation was paramount.

Project Context

Operating under stringent safety and operational protocols, the facility required a solution that could seamlessly integrate multiple surveillance functions.

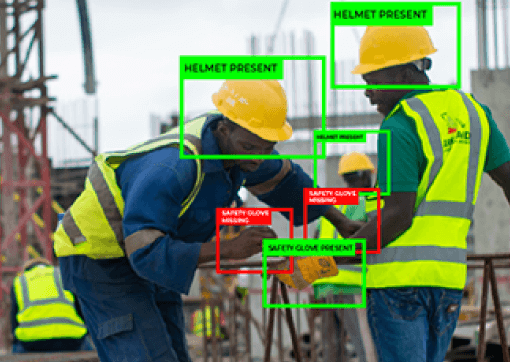

This included managing vehicle entry/exit cycles, monitoring personnel safety through PPE compliance, differentiating between genuine security threats and harmless wildlife, and promptly detecting hazards in high-risk zones such as pump houses and tank farms.

Problem Statement

Manual monitoring and verification at the refuelling farm led to operational inefficiencies and heightened risks.

Traditional surveillance struggled to keep pace with the complex demands of the facility, where delayed detection of unauthorized access, safety non-compliance, or operational hazards could result in significant safety breaches and costly disruptions.

Tools & Technologies

Camera Systems

High-definition, explosion-proof cameras with ANPR and face recognition capabilities are deployed across the facility. These weather-resistant units, equipped with IR and HD features, ensure reliable performance in diverse lighting conditions.

Networking & Storage

A robust network infrastructure is established using Gigabit routers, PoE switches, access points, and CAT6 cabling. A scalable, high-capacity NVR system securely stores and manages extensive video data for real-time analysis.

AI Software

Custom-developed AI algorithms power the system’s core functions, including ANPR for vehicle tracking, facial recognition for personnel safety compliance, and advanced object detection for hazard and intrusion monitoring in critical zones.

Processing Infrastructure

Advanced rack servers with high-performance multi-core CPUs and NVIDIA RTX series GPUs provide the computational power necessary for real-time video processing and analytics, ensuring rapid alert generation and data-driven insights.

Mobile Inspection & Reporting

An integrated mobile application enables field personnel to capture, annotate, and report anomalies instantly, facilitating proactive decision-making and streamlined operational oversight.

Implementation Process

Assessment and Planning

A comprehensive requirement gathering process was conducted in close collaboration with facility stakeholders. This phase involved identifying critical monitoring areas, defining use case requirements, and formulating a detailed, phased implementation plan.

Deployment and Integration

Hardware Installation: Ruggedized, weather-resistant cameras and networking devices were installed strategically throughout the facility to ensure comprehensive coverage, even in challenging environmental conditions.

Hardware Installation: Ruggedized, weather-resistant cameras and networking devices were installed strategically throughout the facility to ensure comprehensive coverage, even in challenging environmental conditions. Software Integration: The AI models—ranging from ANPR to deep learning-based object recognition—were seamlessly integrated with the existing IT infrastructure. Data communication protocols were established to ensure real-time processing and alerting across all modules.

Software Integration: The AI models—ranging from ANPR to deep learning-based object recognition—were seamlessly integrated with the existing IT infrastructure. Data communication protocols were established to ensure real-time processing and alerting across all modules. Training and Optimization:

Post-deployment, the system underwent iterative model tuning based on initial feedback. Customized training sessions were conducted for on-site personnel, ensuring they could effectively operate the system and interpret real-time analytics.

Training and Optimization:

Post-deployment, the system underwent iterative model tuning based on initial feedback. Customized training sessions were conducted for on-site personnel, ensuring they could effectively operate the system and interpret real-time analytics. Continuous Monitoring and Support:

An agile project management approach facilitated regular performance reviews and on-site trials. Continuous monitoring, coupled with proactive stakeholder communication, ensured that the system maintained optimal performance, with risk mitigation measures in place to address any operational challenges swiftly.

Continuous Monitoring and Support:

An agile project management approach facilitated regular performance reviews and on-site trials. Continuous monitoring, coupled with proactive stakeholder communication, ensured that the system maintained optimal performance, with risk mitigation measures in place to address any operational challenges swiftly.